1. Air-Cooled Chillers:

These chillers work with the surrounding air to release heat from the refrigerant, which makes them appropriate for situations where there is a shortage or poor quality of water. The compressor, condenser, expansion valve, and evaporator make up these chillers. Before the refrigerant enters the condenser, the compressor compresses it, increasing its temperature and pressure. The refrigerant condenses into a liquid in the condenser when ambient air takes heat from it. After passing through the expansion valve, the liquid refrigerant’s pressure drops, causing a drop in temperature. Ultimately, heat from the water moving in the chiller system is absorbed by the cool refrigerant as it passes through the evaporator. The procedure is then repeated by cycling the heated refrigerant back to the compressor.

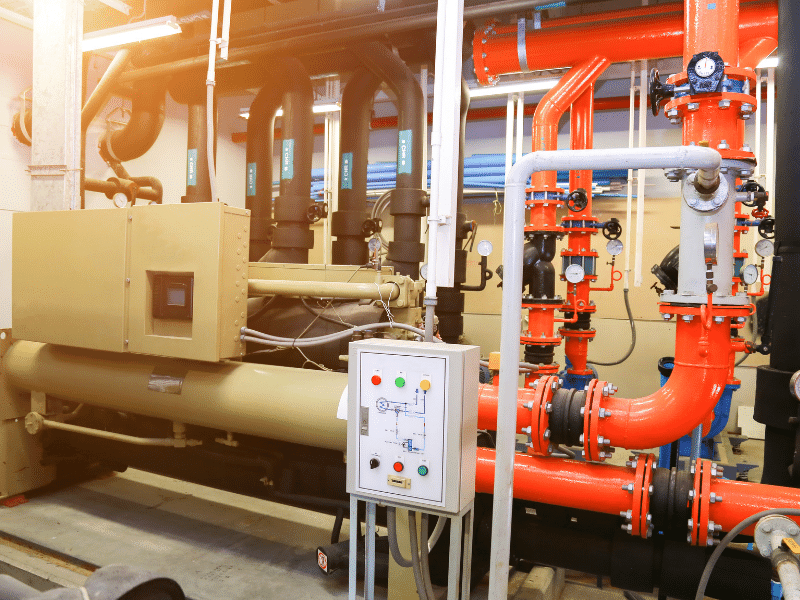

2. Water Cooled Chillers:

To remove heat from the refrigerant, water-cooled chillers use water as a cooling medium. Because water has a higher heat capacity and is a more effective heat transfer medium, these chillers are frequently more efficient than their air-cooled counterparts. The components of a water-cooled chiller usually include an evaporator, cooling tower, compressor, and condenser. Before the refrigerant enters the condenser, the compressor compresses it, increasing its temperature and pressure. The cooling tower’s water absorbs heat from the refrigerant in the condenser, causing it to condense into a liquid. After cooling down, the water is returned to the cooling tower via a circular process. The expansion valve and evaporator allow the liquid refrigerant to collect heat from the chilled water loop before it is sent back to the compressor.

3. Absorption Chillers:

Unlike vapor compression chillers, absorption chillers operate on a distinct cooling principle. To establish a refrigeration cycle, absorption chillers use a combination of a refrigerant and an absorbent solution (usually lithium bromide and water) in place of a compressor. These chillers are frequently utilized in cogeneration systems and industrial processes, among other applications, when waste heat or low-grade heat sources are accessible. The three primary phases of the absorption chiller cycle are regeneration, absorption, and evaporation. When heat is introduced to the refrigerant-absorbent mixture, the refrigerant evaporates and absorbs heat from the chilled water loop during the evaporation stage. In the absorption stage, the absorbent solution subsequently absorbs the vaporized refrigerant. The cycle is completed by heating the absorbent solution containing the refrigerant in the regeneration step, which releases the refrigerant vapor, which is subsequently condensed and returned to the evaporation stage.

4. Centrifugal Chillers:

Centrifugal chillers are a good choice for large-scale commercial and industrial applications because of their great cooling capacity and energy efficiency. Unlike conventional vapor compression chillers, which require reciprocating compressors, these chillers compress the refrigerant vapor using centrifugal force. A compressor, condenser, expansion valve, and evaporator make up centrifugal chillers. The compressor draws in and compresses the refrigerant vapor using an impeller that rotates quickly. After going through the condenser, the compressed refrigerant transfers heat into the cooling medium, which can either be water or air. The refrigerant liquid is cooled and then expanded via the expansion valve to enter the evaporator, where the chilled water loop heat is absorbed. As the refrigerant is pulled back into the compressor, the cycle is repeated.

5. Scroll Chillers:

Scroll chillers are a kind of vapor-compression chiller in which the refrigerant is compressed using scroll compressors. These chillers are well-liked in home and light business applications because of their energy efficiency, quiet operation, and small size. Two spiral-shaped scrolls, one stationary and the other revolving, compress the refrigerant vapor between them in scroll compressors. The components of a scroll chiller usually include an evaporator, condenser, expansion valve, and scroll compressor. Before the refrigerant vapor enters the condenser, the compressor compresses it, increasing its temperature and pressure. The refrigerant condenses into a liquid in the condenser as a result of heat being removed from it. After passing via the evaporator and expansion valve, where it collects heat from the chilled water loop, the liquid refrigerant then goes back to the compressor.

6. Screw Chillers:

Known for their excellent dependability and efficiency, screw chillers compress refrigerant vapor using a rotating screw compressor. In medium-to large-scale commercial and industrial applications where reliable cooling is crucial, these chillers are frequently utilized. The refrigerant vapor is compressed by the meshing of two helical rotors in a screw compressor. The components of a screw chiller usually include an evaporator, condenser, expansion valve, and screw compressor.

7. Hybrid Chillers:

To maximize energy economy and performance, hybrid chillers integrate several cooling technologies, such as vapor compression and absorption. These chillers are made to maximize the advantages of each chilling technique, providing more flexibility and financial savings. Applications with variable cooling loads or fluctuating energy costs frequently employ hybrid chillers. Hybrid chillers enable efficient and dependable cooling operation by dynamically alternating between various cooling modes in response to demand and energy prices.

8. Magnetic Bearing Chillers:

Instead of using conventional mechanical bearings to support the compressor shaft, magnetic bearing chillers use magnetic bearings. Because of this technology, there is less wear and friction, which means less maintenance needs and more dependability. Because of their silent operation, great efficiency, and accurate control, magnetic bearing chillers are a good fit for sensitive settings including data centers, labs, and hospitals. Variable-speed compressors, which are frequently used in these chillers, enable the exact regulation of cooling capacity to correspond with changing load conditions. Magnetic bearing chillers further improve performance and efficiency since they may run faster and are less prone to vibration.