Its job is to reduce the temperature of the refrigerant as quickly as feasible. Because it is located outside, it is susceptible to deterioration and corrosion from exposure to the elements. Damage and gas or refrigerant leaks will result from this. Manufacturers have responded by coating the condenser coil to prevent this problem.

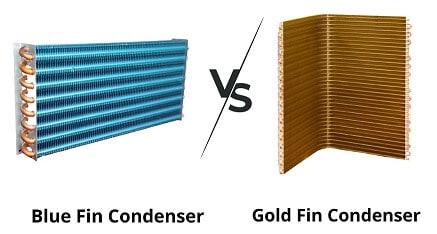

Condenser coils are often constructed from copper or aluminium. There are two common coatings used in most AC units. But these also have their own drawbacks so nowadays blue fin and gold fin are most popular condenser coils materials. Detailed descriptions and the advantages of each version are discussed in this article.

The coils:

These are just a bunch of pipes with a fan placed on top of them. The fan draws in fresh air from the outside and pushes it through the coils. The condenser coils serve this function. Refrigerant flows “through” the condenser coil, while outside air flows “across” the coils to cool the interior. In this manner, the heat radiated by the refrigerant is absorbed, and the refrigerant changes phase from gas to liquid. The resulting hot, high-pressure liquid then travels to the expansion valve.

In a similar manner, the ‘Evaporator Coil’ refers to a system of pipes that lead from the furnace. By doing so, warm air is absorbed from the indoor air. Air ducts then allow the cooled air to be distributed throughout the space. The cycle repeats again by re-introducing the refrigerant to the compressor.

Condenser coils have proven to be an essential part of any working air conditioner. These are made up of copper and aluminum, but now new coatings like a gold fin and a blue fin are becoming popular. The ‘Fins’ ensure the proper operation of the coils as a whole. The fins are anti-corrosion coatings applied to the condenser coils. This contributes to the air conditioner’s improved efficiency.

Blue fin condenser technology:

Epoxy is a resin substance that coats condenser coils or fins in this design. Blue fin technology gets its name from the fact that the coating makes the coils look blue rather than golden.

Epoxy’s exceptional qualities stem from the fact that it is a hydrophilic chemical. Protection against corrosion and humidity in both hot and salty situations are provided by the coils’ resistance to the elements.

As a result of its low surface tension, the coating creates extremely little resistance when submerged in water. Water or moisture droplets will therefore roll off the coils. Bacteria, fungi, and viruses would not be able to multiply there.

Epoxy does not react with environmental salts or acids. Salts, acids, minerals, and other impurities in the air are prevented from accumulating. This results in clean fins and unimpeded airflow.

Advantages of blue fin technology:

A blue fin condenser coil has the following advantages:

- Maintains the air conditioner’s reliability and efficiency over time.

- Increases cooling efficiency by enhancing heat transfer.

- The energy efficiency of air conditioner improves as a result.

- Blue fin condensers offer low-cost, high-reliability solutions.

- Since it is so cheap, it is typically found in less cost AC units.

Gold fin condenser technology:

The process involves applying a gold nano coating to the coils of an air conditioner. Titanium dioxide is used in the gold coating process by several manufacturers. It will shield the coils from the harsh weather and other elements and keep them in good working order.

In the same way as blue fin coating shields against rust and corrosion and the effects of weather, water droplets, acid and air salts, so too does gold fin coating. Because of how well it transfers heat, this coating improves the condenser’s performance.

It is an improvement over earlier technologies since it does not compromise the condenser coils’ inherent conductivity. In this way, a very low temperature can be reached by the refrigerant. Therefore, it can absorb more heat from the useful space.

Advantages of gold fin technology:

Here are some of the advantages of using a gold fin condenser: All the benefits of bluefin technology are present in gold fin condensers, and more.

- Extra defense for the condenser coils against the elements

- Increased energy efficiency in cooling systems due to enhanced heat transfer rates

- Totally green and risk-free technology

- The condenser will last longer as a result.

- Because of its portability, this technique has found widespread application in both coastal and other regions.

Hydrophilic blue fin:

Corrosion, which occurs during heat transmission, is harmful to an air conditioner’s coils and hence its longevity. Because of the deterioration, the refrigerant leaks out of the coils. The presence of salts and ozone in coastal air makes this phenomenon more common in coastal areas than in other areas. If you keep the coils clean, you can keep them from breaking.

However, cleaning the aluminum coils that are stored in the bulky cabinets is a challenge. Aluminum coils are fused to copper tubes during production, resulting in galvanic corrosion. Galvanic corrosion occurs when two distinct types of coils are accidentally combined. To prevent galvanic corrosion, producers use a technique called Hydrophilic Fin Technology, in which a hydrophilic golden coat is applied to aluminum coils.

Advantages of hydrophilic blue Fins:

- Hydrophilic technology prevents the accumulation of water on the surfaces of the fin.

- The water drops roll off the condenser’s surface without accumulating.

- It is the same thing as the coils’ epoxy coating.

- The hydrophilic coating on the aluminum fins has a lifespan three times that of the metal itself.

- This is the most effective method for protecting coils against moisture and rust.