Ductwork Fabrication:

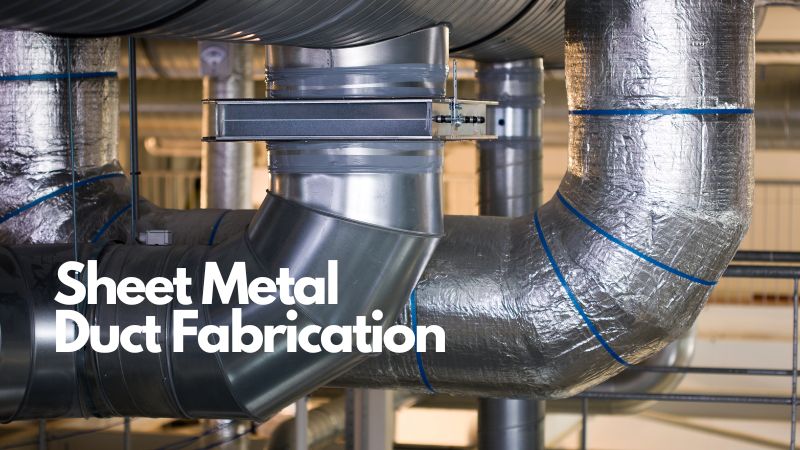

The building of ductwork is one of the main uses of fabricated sheet metal in HVAC. The ducts in a building are the pathways that the air conditioning or heating system uses to transfer air from one area to another. Ductwork is best constructed from fabricated sheet metal because of its adaptability, longevity and customizability.

To meet the demands of any building’s HVAC system, fabricated sheet metal ductwork is available in a wide range of sizes and shapes. There are a variety of popular shapes for ducts, including rectangle, circular, oval, and spiral. The benefits of each shape vary based on factors like available space, airflow needs, and personal design preferences.

Sheet metal components are formed into seamless duct sections during the fabrication process, which includes cutting, bending, and assembly. For optimal airflow performance and airtight sealing, precision is key. The use of cutting-edge technology like computer numerical control (CNC) machining and laser cutting allows for exact manufacturing, leading to ducting that exceeds all performance and efficiency standards set by the industry.

Enclosures and Cabinets:

Enclosures and cabinets for HVAC equipment, as well as ducting, are commonly built using fabricated sheet metal. Protected from the weather and designed for safe operation, these housings include components including air handlers, compressors, and condensers.

Excessive humidity, severe temperatures, and corrosive substances are just some of the things that fabricated sheet metal enclosures are made to endure. Because of its high strength and long lifespan, this material is ideal for protecting delicate HVAC systems.

In addition, different equipment configurations and space constraints can be accommodated by customizing fabricated sheet metal enclosures. The usefulness and accessibility are enhanced by integrated features like ventilation openings, cable management provisions, and access openings, which make maintenance and serviceability easy.

Air Distribution Components:

The production of several air distribution components for HVAC systems also makes use of fabricated sheet metal. Important components for regulating and directing airflow in a structure are louvers, grilles, registers, and diffusers.

One example is the use of diffusers, which are mounted on the ceiling or walls and disperse conditioned air uniformly across the space. Diffusers, which are made of sheet metal, have intricately designed patterns that maximize airflow with minimal noise and turbulence. Grilles and registers, on the other hand, are decorative and useful components of HVAC systems; they allow air to enter and exit the ducting.

Another crucial part of the air distribution system made of sheet metal is the louver. Their purpose is to let air to circulate inside a structure or mechanical enclosure while blocking the passage of moisture and other particles. Fabricated louvers provide both form and function, and they can be tailored to fit any application with their wide range of sizes, shapes, and configurations.

Architectural Applications:

Fabricated sheet metal isn’t only used in HVAC systems; it may also be found in architectural features that deal with HVAC. Architectural elements that use fabricated sheet metal to improve the look and functionality of buildings include metal cladding, fascia panels, and ornamental grilles.

To provide protection from the elements, insulation from heat loss or gain, and aesthetic appeal, metal cladding systems encase building exteriors in prefabricated sheet metal panels. These panels can be tailored to satisfy specific performance standards while also enabling architects and designers more freedom to express their creative visions through the use of various textures, finishes, and shapes.

Fabricated sheet metal is used to create consistent exteriors that blend in with the building’s architecture. Fascia panels are commonly utilized to hide rooftop HVAC equipment. Ensuring a cohesive and visually acceptable look, these panels can be customized to match specific equipment specifications and mounting requirements through precision manufacturing procedures.

FAQs:

-

How Often Should Aircon Be Serviced In Singapore?

It is recommended that air conditioning units in Singapore undergo maintenance at least once a year to guarantee optimal performance. The high humidity and continuous usage of air conditioning machines necessitate frequent maintenance to avoid malfunctions, guarantee optimal performance, and prolong their lives. Indoor air quality is particularly important for health and comfort in a tropical environment like Singapore’s, and clean filters and coils help achieve that. For units that get a lot of use or are in dusty areas, some homeowners choose to have them serviced every six months. To keep air conditioners functioning properly in the hot and humid weather of Singapore, routine maintenance is essential.

-

Does My Aircon Need Servicing?

If you want your air conditioner to keep running at peak efficiency, you need to get it serviced often. Reduced airflow, unusual noises, foul odors, and inconsistent cooling are all indicators that it needs servicing. Furthermore, an ineffective air conditioner could be the cause of your unexpectedly increased energy expenditures. Regular maintenance extends the life of your air conditioner by keeping the filters clean, the coils clear of dirt, and the refrigerant levels just right. To keep your air conditioner in top shape and prevent breakdowns, it is suggested to get it serviced annually, preferably before the cooling season begins.

-

How Often Should You Have A Professional Inspect And Service Your Air Conditioner?

Depending on how often you use your air conditioner, you should clean or replace the filter every one to three months to keep it running well in between professional servicing visits. To maintain enough airflow, you should clear the area surrounding the outdoor unit of any debris, like leaves or branches. Look for leaks or rust or other obvious indications of damage or wear on the outside and inside units, and fix them right away. To further prevent dirt and debris buildup, you can use a soft brush to gently clean the coils and fins. Finally, think about setting up routine inspections to spot problems early on.