VRF Systems: What Are They?

Advanced HVAC solutions known as Variable Refrigerant Flow (VRF) systems use refrigerant as the main heating and cooling medium. Refrigerant piping connects one or more outside units to several inside units in a VRF system. The inverter-driven compressors of the outside unit control the refrigerant flow according to the heating or cooling requirements of each building zone.

The zoning features of VRF systems, which enable separate heating or cooling of distinct parts of a building, are especially well-known. Heat recovery VRF systems are extremely energy-efficient in mixed-use settings because they allow some zones to concurrently heat and cool. VRF systems are a great option for buildings that need precise temperature management because of their versatility.

A Chiller System: What Is It?

Conversely, chillers are centralised systems that cool using water or a water-glycol blend. To control indoor temperatures, these systems circulate chilled water through fan coil units (FCUs) or air handling units (AHUs) after cooling it to the appropriate temperature.

There are two primary varieties of chillers: water-cooled and air-cooled. Water-cooled chillers use cooling towers to release heat, which makes them more efficient but also more difficult to install and maintain than air-cooled chillers, which release heat directly into the atmosphere. Large buildings and industrial establishments that need a significant amount of cooling capacity frequently utilise chillers.

Cooling Medium: Water vs. Refrigerant

The cooling medium that VRF and Chiller systems employ is one of their primary distinctions. Refrigerant serves as the direct heat transfer medium in VRF systems. There is no need for intermediary systems like water pipelines because the refrigerant travels from the outdoor unit to the indoor unit.

On the other hand, the cooling medium in chiller systems is either water or a water-glycol mixture. To provide cooling, a system of pipes distributes chilled water throughout the building. The difference between chillers and VRF systems is this indirect cooling technique. Chillers are perfect for applications needing large-scale cooling, although VRF systems are better suited for smaller installations.

Temperature Control And Zoning:

When it comes to zoning, VRF systems are excellent. With a VRF configuration, each indoor unit may be controlled separately, enabling accurate temperature adjustments in various building zones. For multi-use facilities, such as hotels or offices, where tenants in different sections may have differing comfort preferences, this is especially advantageous. Furthermore, heat recovery VRF systems allow synchronised heating and cooling in separate zones, thus boosting their versatility.

Although they can serve many zones, chiller systems are not as precise in zoning as VRF systems. AHUs or FCUs, which distribute the cooled air, are responsible for controlling the temperature in chiller systems. Therefore, with chiller-based systems, it may be more difficult to achieve individual zone management.

Installation Requirements and Space:

Another difference is the amount of room needed for HVAC equipment. VRF systems are small and don’t need a lot of ductwork or centralised mechanical rooms. They are perfect for retrofits and small to medium-sized structures because of their modular form, which makes installation simple in limited spaces.

The chiller unit, water pumps, and pipes, on the other hand, take up a lot of room in chiller systems. Cooling towers are also required for water-cooled chillers, which raises the infrastructure needs. Because of this, chillers are better suited for large-scale applications where space is not a major factor.

Cost Factors:

Because of their sophisticated technology and zoning features, VRF systems usually have a higher initial cost. But over time, especially in buildings with variable loads, their energy efficiency and reduced operating costs can make up for the initial investment.

On the other hand, particularly in air-cooled configurations, chiller systems frequently have lower initial costs per tonne of cooling capacity. Despite being more energy-efficient, water-cooled chillers come with a higher upfront cost because they need more cooling towers and other infrastructure. Additionally, chiller system operating costs may be higher, especially in areas with significant temperature fluctuations.

Applications:

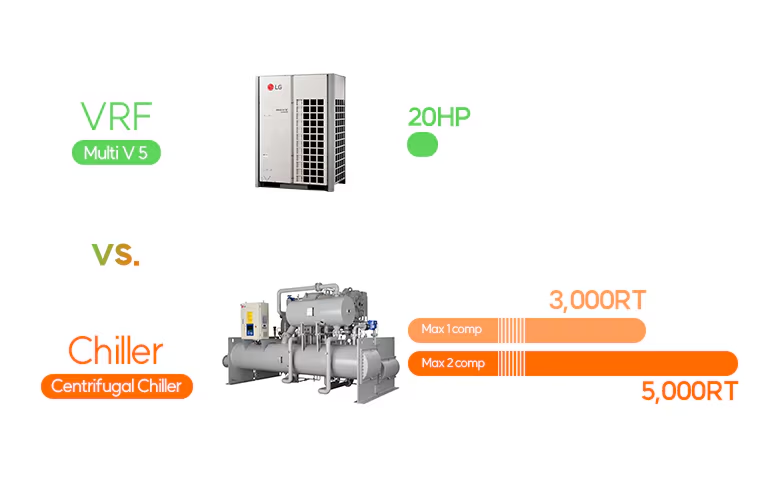

Small to medium-sized buildings, including offices, hotels, and retail establishments, are the ideal choices for VRF systems. They are perfect for multipurpose settings since they may offer customised temperature control. When upgrading older buildings, where it would not be possible to install significant piping or ductwork, VRF systems are also the ideal option.

In contrast, large buildings and facilities with heavy cooling requirements—like data centres, hospitals, airports, and industrial plants—are best suited for chiller systems. They are essential in large-scale applications where centralised cooling is needed due to their scalability and great cooling capacity.

Final Thoughts:

Although both VRF and Chiller systems are efficient HVAC options, they have diverse uses and are suitable for different kinds of buildings. VRF systems are perfect for small to medium-sized buildings because of their excellent zoning capabilities, energy economy, and ease of installation. Large facilities with substantial cooling requirements are better-suitable for chiller systems due to their centralised operation and considerable cooling capacity.

Frequently Asked Questions:

1. How Important Is GWP For Refrigerants, And What Is It?

The amount of heat that a greenhouse gas retains in the atmosphere in comparison to carbon dioxide is measured by its global warming potential or GWP. Refrigerants with lower global warming potential (GWP), such as R-32, are more environmentally friendly choices for cooling systems.

2. How Do Homeowners Are Affected By Refrigerant Regulations?

High-GWP refrigerants have been phased out by environmental rules such as the Kigali Amendment and the Montreal Protocol, which have promoted the use of sustainable substitutes. Homeowners that have older systems would have trouble locating R-22 for repairs; thus, they should think about replacing them with more recent, compliant systems.