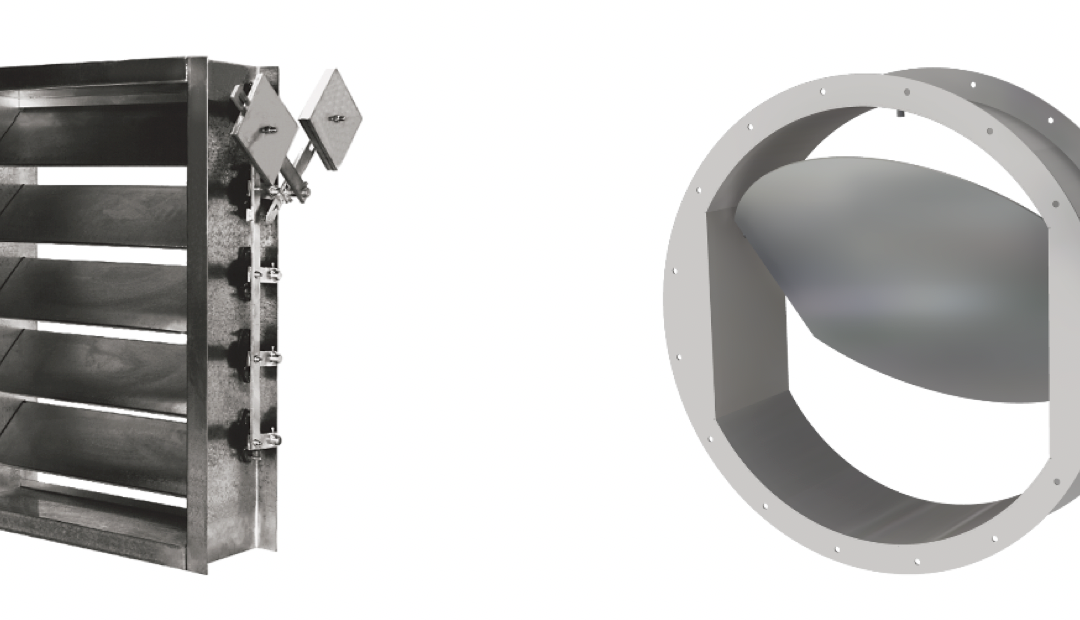

Parallel Blade Dampers:

In heating, ventilation, and air conditioning systems, a frequent type of damper is the parallel blade damper. Achieving fine control over airflow is made possible by these dampers’ blades, which move in tandem with one another in a parallel motion. You can control the airflow through the ducts by adjusting the blades to different angles. Parallel blade dampers are perfect for commercial buildings with various occupancy areas or any other situation where precise temperature control is required.

To make them long-lasting without adding a lot of weight to the HVAC system, parallel blade dampers are typically built with lightweight materials such as aluminium or galvanized steel. These dampers can also be programmed to operate automatically, which allows for more efficiency through interaction with building management systems and remote control.

Opposed Blade Dampers:

When compared to dampers with parallel blades, those with opposed blades work on a different basis. A better balanced management of airflow is achieved in opposing blade dampers by having the blades move in different directions. Large commercial rooms and industrial settings are ideal examples of situations where this design shines: where even air circulation is paramount.

Airflow is improved and turbulence is reduced by using blades in an opposing arrangement. This helps with energy efficiency since it lowers the system’s overall energy usage by reducing the resistance it encounters. In order to keep the air circulation in a building consistent, opposed blade dampers are installed in the supply and return air ducts.

Louver Dampers:

A dual-purpose device, louver dampers integrate the functions of both louvers and dampers. In order to let airflow while shielding from weather conditions like rain and snow, these dampers use slats or blades installed at an angle. For external air intakes or exhausts, louver dampers are a common choice since they regulate airflow and protect the system from weather.

In situations where precise control of the airflow is required, louver dampers are an invaluable tool due to their adjustable blades, which allow for adjustment of the volume of air entering or leaving the system. Commercial buildings, warehouses, and industrial facilities frequently use this sort of damper since it is essential to maintain a balance between airflow and environmental conditions.

Butterfly Dampers:

Butterfly dampers, sometimes called disk dampers, have a rotating disc or vane that spins inside the duct. They are straightforward to install and maintain because of how simple they are. When a complete and immediate stoppage of airflow is needed, butterfly dampers are ideal, and they are commonly installed in circular ducts.

Butterfly dampers allow for precise control of airflow through the rotation of a circular disk at varied angles. Butterfly dampers are great when efficiency and simplicity are key, but they are not as precise as parallel blade dampers. Typical applications include air conditioning systems in homes and businesses that use circular ducting.

Factors Influencing Damper Selection:

Several considerations go into selecting the best damper for an HVAC system. Considerations such as the building’s nature, the size and design of the HVAC system, the desired level of control, and local temperature conditions are taken into account when choosing a damper.

-

Building Type and Purpose:

The air conditioning needs of various building types are unique. For instance, the precise control provided by parallel blade dampers could be useful in commercial facilities with different occupancy zones. But, due to their efficiency and ease of use in circular ducts, butterfly dampers may be preferred by manufacturing facilities. When choosing dampers, it is essential to have a clear understanding of the building’s purpose and layout.

-

System Design and Size:

When choosing dampers, it is important to keep the HVAC system’s size and design in mind. Opposed blade dampers are ideal for larger systems because they regulate the airflow in a balanced manner and can manage higher volumes of air. On the other hand, butterfly dampers might be better suited to smaller home systems because of their space efficiency and simplicity.

-

Need for Automation and Control:

Technological progress has allowed for the automation of heating, ventilation and air conditioning systems, which in turn allows for remote control and connection with building management systems. For such uses, the precise control provided by motorized actuators makes parallel blade dampers an excellent choice. If you want to pick dampers that are efficient and convenient, you need to know what a building needs in terms of control and automation.

-

Environmental Considerations:

Outdoor air intakes and exhausts frequently make use of louver dampers due to their resistance to weather conditions like rain and snow. To keep the HVAC system running smoothly and efficiently in severe weather, damper selection is heavily influenced by regional climate.

Installation and Maintenance:

It is essential for every HVAC component to be easy to install and maintain. The straightforward design of butterfly dampers makes them more user friendly in terms of installation and maintenance. The installation of parallel and opposing blade dampers may necessitate greater care for optimum performance, despite the fact that they provide precise control.

If you want your dampers to be long lasting and work well, you need to maintain them regularly. Maintenance such as checking, cleaning, and lubricating moving parts on a regular basis helps to keep things running smoothly. It is critical for HVAC technicians and building managers to know how to properly maintain each kind of damper.